The ARP Manufacturing Process

In order to ensure optimum quality control, ARP has grown to be exceptionally self-reliant and now controls all aspects of the manufacturing process. All operations are performed in-house and closely monitored. This is how ARP has been able to establish a reputation for "zero defects" quality throughout the industry.

Material comes from the mill in large coils...which subsequently will be fed into cold-headers and formed into bolts.

The process begins right at the mill, where ARP orders only premium grade materials including several proprietary alloys. The ever-popular 8740 chrome moly steel, for example, comes from the mill in four distinct grades. The lowest is "commercial," which is followed by "aircraft quality." ARP uses only the top two grades (SDF and CHQ), which cost twice as much, but provide the foundation for defect-free fasteners. These materials come in bar stock (for studs) and huge coils (for bolts).

Most ARP fasteners start off on a cold header, where the high quality wire is cut to length and the head and shank are formed in a multi-stage forging process that contributes to the strength of the overall fastener. A few of our fasteners are cut from bar stock and hot headed.

ARP's bank of cold-headers can handle material up to 5/8˝ diameter and form bolts in a multi-phase operation.

The Grinding Department is where all studs are centerless ground to ensure that they are concentric and straight.

Following the cold/hot forging, material is heat-treated to desired levels. This crucial process is done entirely in-house to assure total quality control. ARP uses custom vertical racks to hold each piece individually and assure complete 360° penetration. This is far superior to commonly-used methods of dumping items into a large bin and batch-treating.

Heat-treating is critically important in obtaining the correct tensile strength. Fasteners are placed in special vertical racks to ensure complete 360° penetration.

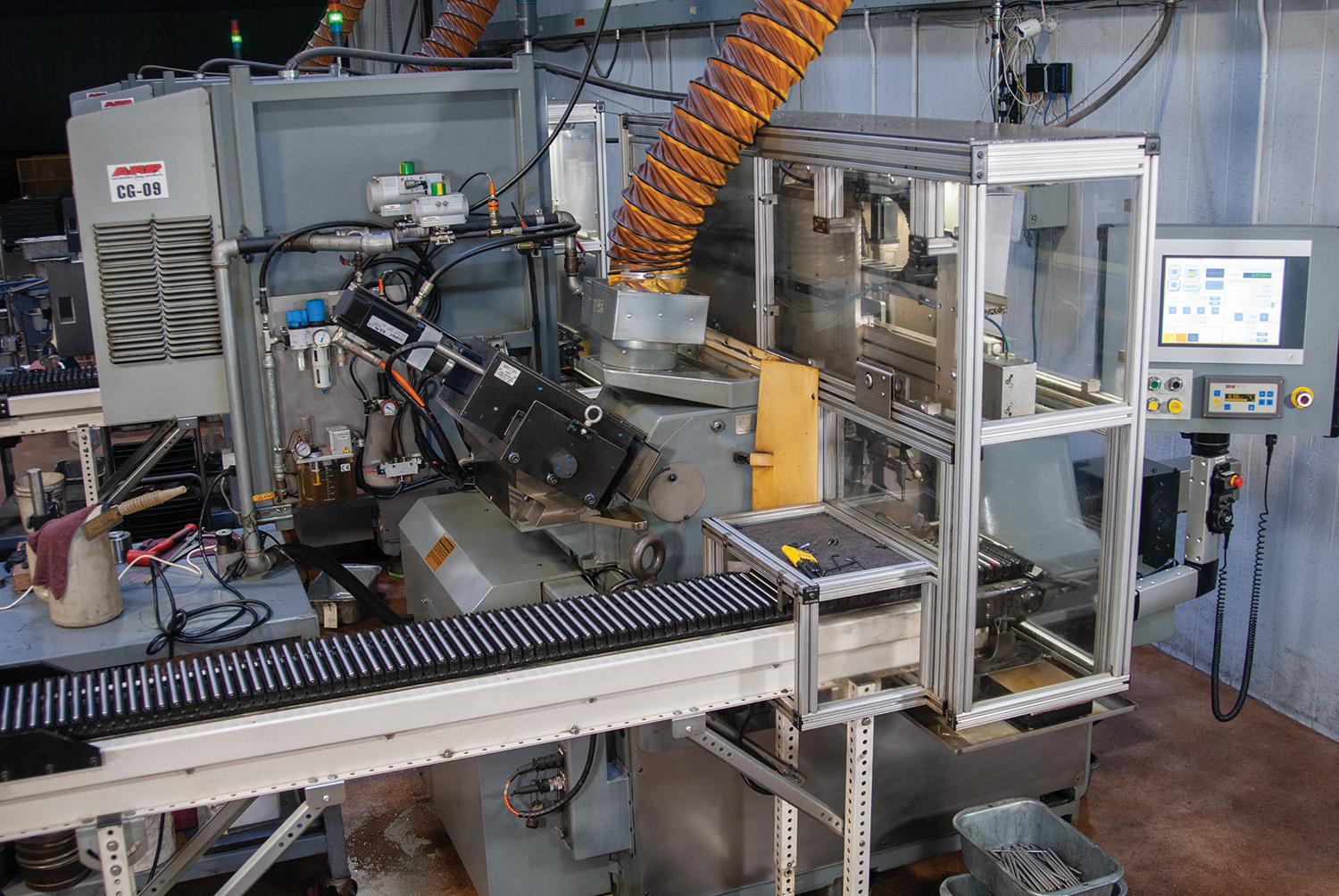

An overview of part of ARP's expansive machining operations. The shop is laid out for optimum efficiency.

Studs are centerless ground to guarantee concentricity. The thread rolling operation (to MIL-S-8879A specs) is done after heat-treat, which accounts for a fatigue strength up to twenty times higher than fasteners which are threaded prior to heat-treat.

ARP manufactures nuts in a multi-step process that begins with raw material being fed into a giant forming device that "blanks" the hex and 12-point nuts and continues with highly sophisticated, automatic tapping machines that tap each nut with an accuracy of .001˝ (which is five times higher than the aerospace standard). This ensures an exceptionally close-tolerance fit between the bolt/stud and nut.

Proprietary high quality stainless steel blanks are fed into the nut-forming presses by the thousands.

A series of CNC-threading machines are employed by ARP to accurately tap the threads in nuts. Tolerances held are better than aerospace standards.

A bank of CNC machining centers are employed at ARP to perform specialty operations.

State-of-the-art EDM technology is used to perform special operations, such as hex-broaching head studs.

Metal finishing is also performed in-house at ARP. Operations include black oxide coating of chrome moly or polishing stainless steel to a brilliant luster.

Fasteners are shot-peened to improve fatigue life.

The finishing touch for most chrome moly fasteners is the black oxiding operation.

Also on the premises is a fully-equipped lab for R&D and quality control. It has everything required to ensure that ARP products measure up to the company's ultra high standards. Some of the tests that ARP personnel perform on a daily basis include ultimate tensile strength (using a 120,000 lb. capability tensile machine), fatigue cycle (Amsler) and hardness (Rockwell). Visual inspections include use of an optical comparator (to check thread root contour, etc.), fixtured micrometers and microscopic grain flow analysis.

The finished goods are given a protective coating and stored in sealed containers, awaiting packaging. Millions are in stock!

Components for each kit are placed on the appropriate display cards, sealed and labeled. Through-put has been significantly increased.

High powered magnifiers are used to carefully inspect critical components. ARP's quality control team is relentless!

ARP has two highly sophisticated Amsler fatigue machines, which test fasteners through millions of cycles.

The computer-controlled fatigue cycle testers allow ARP to take fasteners to a failure point in millions of cycles – as opposed to the aerospace norm of 65,000 average to 130,000 cycles maximum. This allows ARP engineers to verify the design specifications of each fastener, and prove its ability to provide superior long-term service.

Finished products are packaged and warehoused in ARP's Ventura facility, which is also home to the firm's customer service, technical and sales office.