The "Aerospace Quality" Myth

An interview with Gary Holzapfel by Carroll Smith

In areas from hose ends to engine fasteners the terms "Aerospace material and Aerospace Quality" have become buzz words implying the very best in design, materials and quality control.

"It isn't necessarily so", says Gary Holzapfel, founder and CEO of Santa Paula, California based ARP, Inc. ARP (Automotive Racing Products) supplies extremely high strength and fatigue resistant threaded engine fasteners to NASCAR, IndyCar, NHRA, IMSA and Formula 1 engine builders and manufacturers. Holzapfel explained his reasons in an interview with Carroll Smith.

Smith: "Gary, do you believe that the term 'aerospace quality' is over rated in the specialty fastener industry?"

"Yes I do. First of all, the term is meaningless. Any AMS (Aerospace Material Specification) material must be matched to the specific application. As an example, some airframe bolts (AN3-20) are legitimate 'aerospace parts' and are very well suited for the low stress applications for which they were designed. But with a minimum ultimate tensile strength of 125,000 psi, and a relatively low temperature limit, they would be completely unsuitable for use in a racing engine.

We started out in the aerospace fastener business and we understand it. That's why we're not in it any longer. What is not generally understood about aerospace fasteners is that the fastener manufacturers do not design the product. The nuts, bolts and studs are spec'd by the airframe or engine designers and put out for bid. As long as the supplier certifies that the product meets the minimum requirement of the specification and it passes the customer's inspection procedures, low bid wins."

Smith: "Are you implying that the aerospace fastener manufacturers cut corners in order to win contracts?"

"No, it's a matter of manufacturing goals and simple economics. The aerospace market is price dominated. In order to get the contract, the fastener manufacturer's goal is to meet the specification at the least cost, not to produce the best possible part.

This means that they are going to use the least expensive steel and manufacturing processes that will meet the specification. There is nothing wrong with this approach.

It certainly does not mean that certified aerospace fasteners are unsafe in any aspect. They will do the job for which they were designed.

There is another factor. Airframe and aircraft engine manufacturers design their components to a very high margin of safety. Further, aerospace structures are designed to be 'fail safe.' There is a back up or second line of defense for virtually every structural component so that an isolated failure will not lead to disaster. They are also subjected to frequent and rigorous inspections."

Smith: "What's different about motor racing?"

"Quite a lot, really. While the demands for strength, fatigue resistance and quality control can be similar, and the assembly and inspection procedures in racing can be as rigorous as aerospace, in professional racing very few parts are over designed and there are no fail safe features.

There are no back up provisions for component failure. A failed (or even loosened) nut or bolt in a racing engine means disaster – instant catastrophic failure. An expensive engine is destroyed and a race is lost.

That is why random failures are unacceptable in motor racing, and why aerospace standards should be only a starting point. This means that a specialist in the production of high performance engine fasteners must design and manufacture the very best fasteners that can be produced."

Smith: "So where does the production for a new racing fastener begin?"

"The design process begins with the customer's requirements – the operating conditions and loads to be expected, the packaging constraints and the weight and cost targets. This allows us to select the optimum material for the part, and to do the initial mechanical design.

Failed valve spring retainer – the result of faulty metallurgy at the fastener supplier.

This is done primarily through computer modeling and includes stress analysis and fatigue testing. I should point out that stress in a fastener is not just tension. It also includes shear and bending loads. In addition, because racing engine fasteners are used at elevated temperatures – they remain under load for hours, rather than seconds – thermal stress considerations, elevated temperature strength and fatigue become part of the picture.

All of these factors determine the choice of material – not just ultimate tensile strength and material specification numbers. When we are happy with the computer modeling, we develop prototype parts that are manufactured and tested under actual race conditions. If and when we're satisfied, the design is finalized and we write the manufacturing specification."

Smith: "How important is the choice of material?"

"Extremely – at every level. The racing engine builder expects to receive components from us that are at the required hardness, with the correct thread and concentricity tolerances and with no inclusions or defects in the steel.

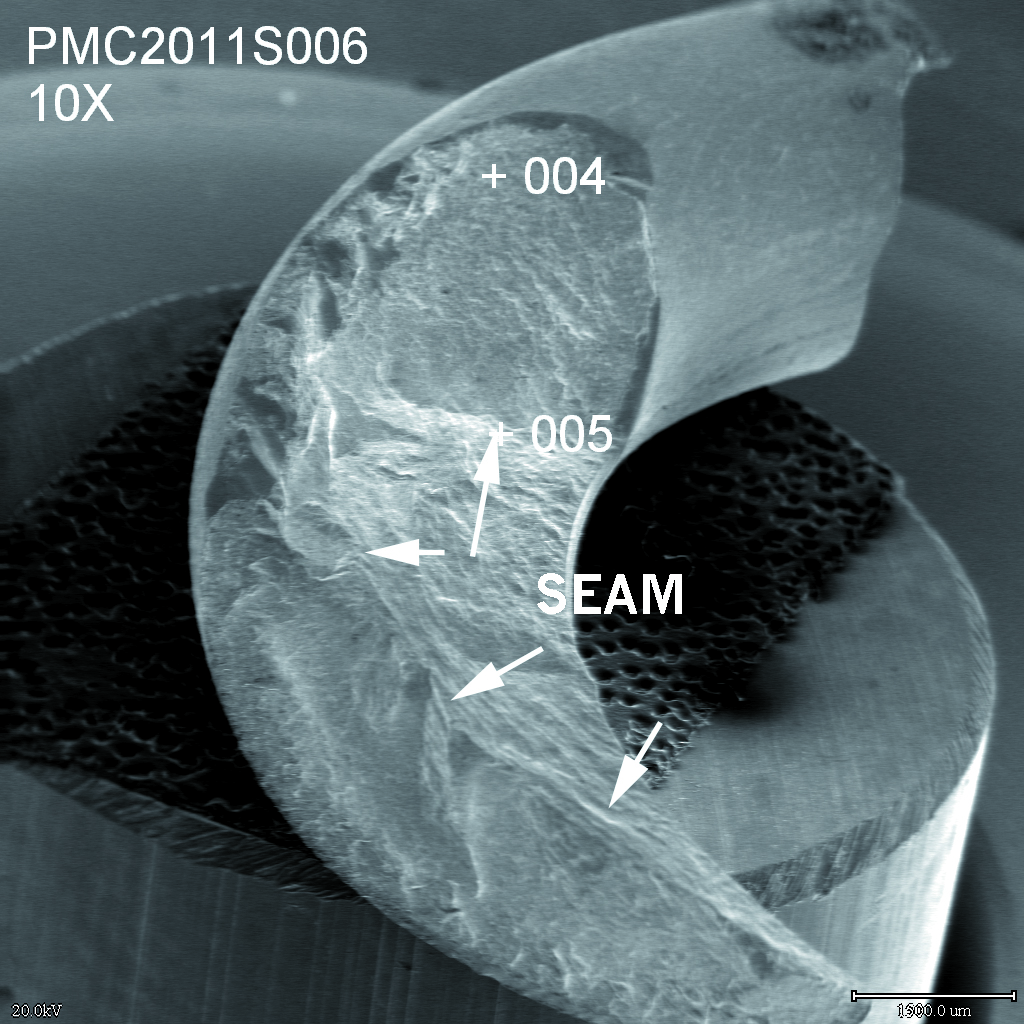

Magnified inclusions found during examination of the grain structure of special alloy steel.

Our inspection begins at the steel supplier's plant. We specify the steel supplier, the method of manufacture and the required chemical properties. Our quality control people are there during manufacture. Before we accept it, we actually take samples from every piece and do both chemical and mechanical evaluation – that includes ultrasonic, magnetic particle and dye penetrant inspection to ensure that there are no cracks or inclusions.

In fact, inclusions in the grain of the steel are a leading cause of fatigue failures and consequent engine damage. So we're extremely concerned with what's happening inside the steel when it is still a red-hot billet. Not only will inclusions cause failure, but inclusions and impurities cause hardening during the heat-treat process to be inconsistent. Again, this is not a concern with aerospace, but it can't be tolerated in racing engine fasteners where catastrophic failure of even one fastener can ruin a race."

Smith: "What about the manufacturing processes?"

"I'm glad you asked. There is a widely held misconception in our industry that simply by using the same materials as ARP, other manufacturers can duplicate our products.

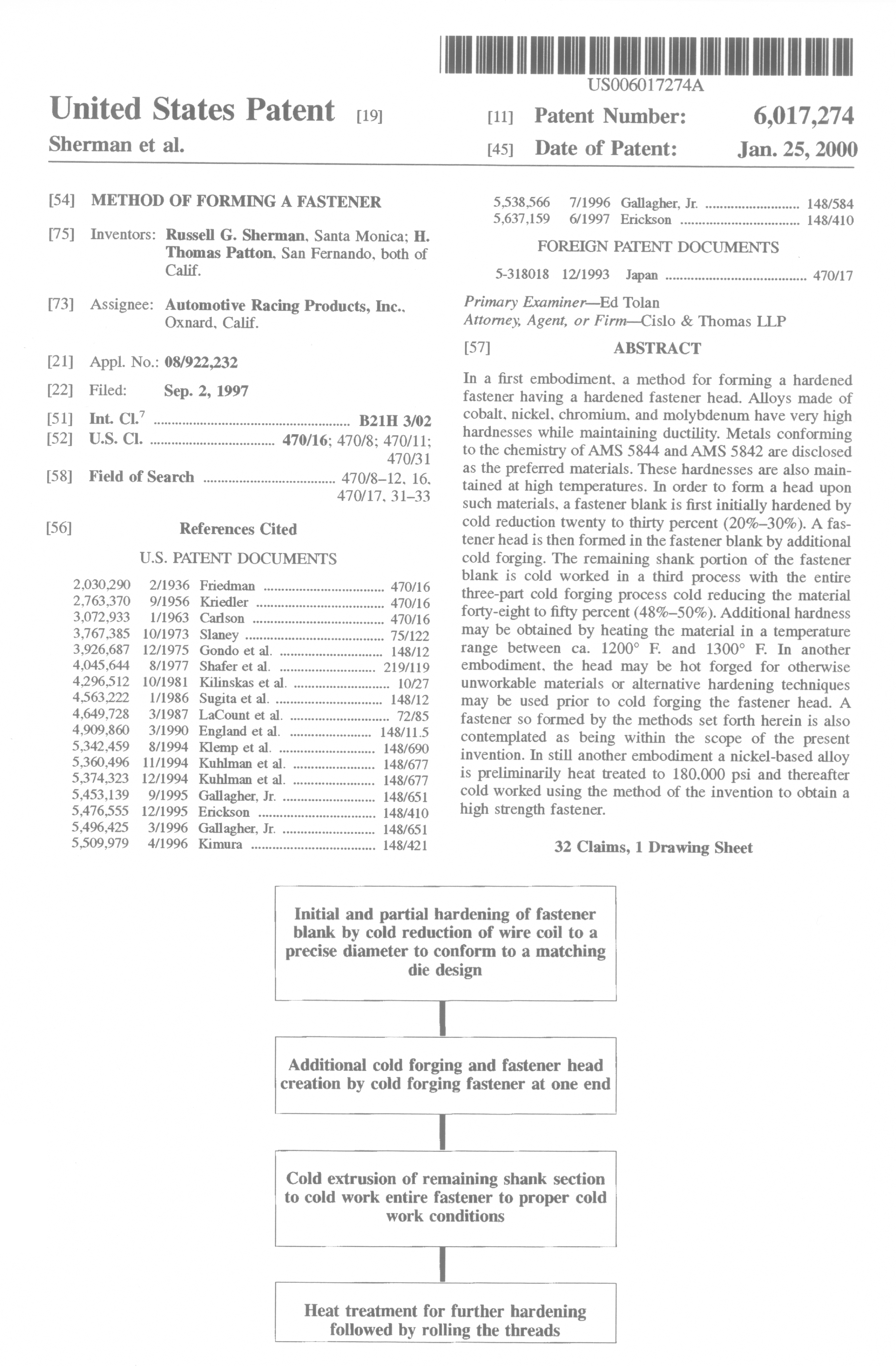

Close-up of main cap bolt that failed as result of decarburization during heat treat by supplier.

It just isn't so. As an example, steel can become decarburized during heat-treating. Even with a knowledgeable metallurgist, this can happen if the heat-treating procedure is not strictly followed.

ARP uses atmosphere and vacuum controlled ovens, heated with electricity or with controlled and filtered gas burners to very close tolerances. The oven's temperature is tracked by computers throughout the heat treating procedure and we do our own Rockwell and tensile testing at several stages of production. Because the actual strength of a fastener is determined by the quality of the heat-treatment, inconsistent hardening automatically equals inconsistent product. That may be acceptable in the aerospace world but not in motor racing.

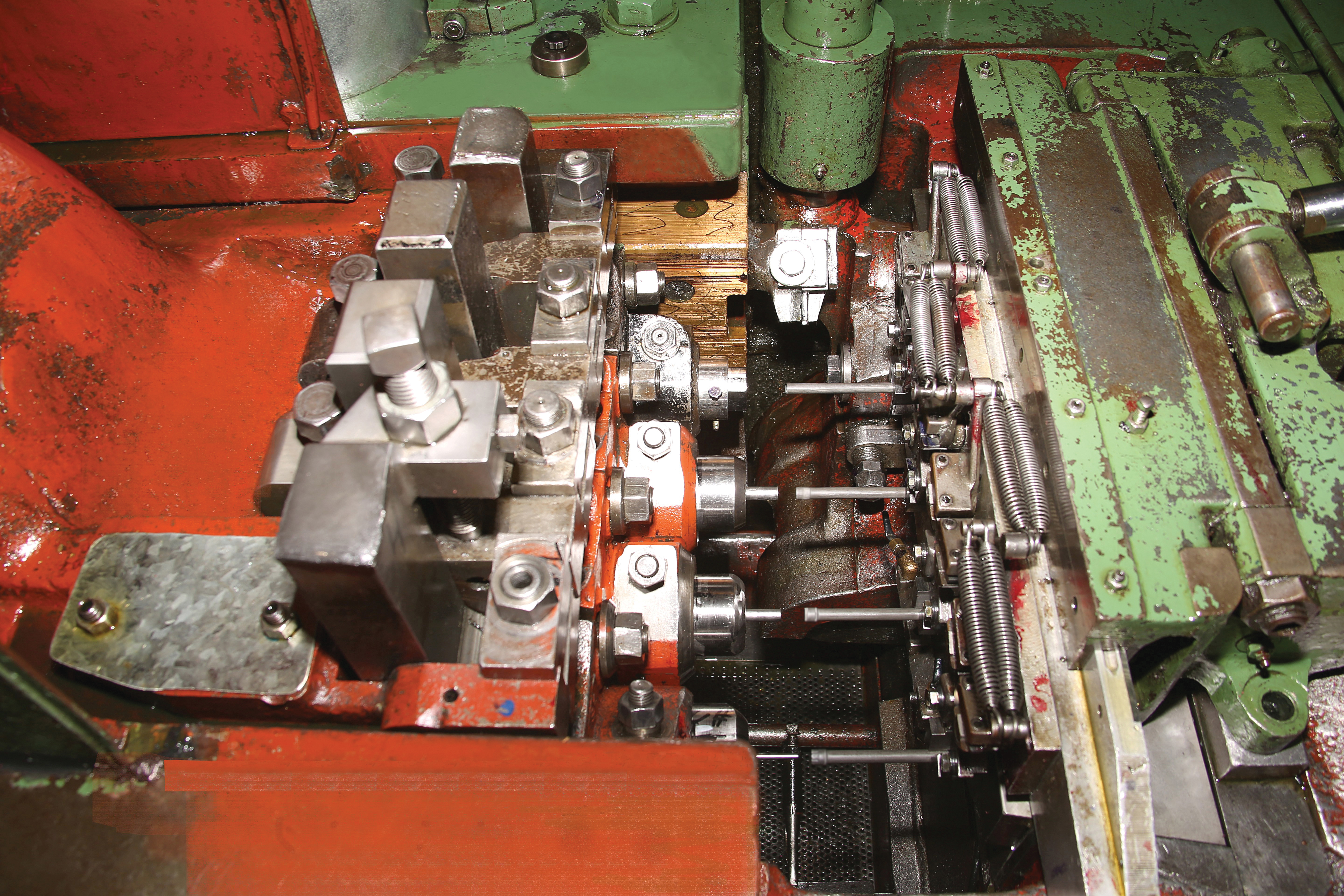

The same is true of thread rolling. Temperature and die speed must be controlled and changed for different alloys. Many bolt manufacturers who meet the Aerospace Specifications don't come close to meeting our standards. We consistently go beyond standard aerospace specs.

Our concern with the manufacturing processes extends to the details of heat-treating, shot-peening, fillet rolling and grinding – down to the frequency of dressing the grinding wheels. In the arena where aerospace standards are a starting point and random failures are unacceptable, I feel ARP stands alone as a primary engineering and manufacturing source for specialty and custom fasteners for use in motorsports.

It is important to realize that simply quoting an AMS (Aerospace Material Specification) number without strength and percentage of elongation numbers is meaningless. Statements that the use of a particular material will, in itself, result in extreme strength and resistance to fatigue can be misleading. In the world of high strength alloys, whether they are used for bolts or for landing gears, the manufacturing processes are at least as important as the material specification.

Some in our industry claim to inspect materials at the 'molecular' level. In metallurgical terms, molecules are not necessarily part of the vocabulary. Our engineers tell us that talking about molecules is misleading. When reference is made to metal, it is typically in terms of atom structures. We routinely check metallurgical features microscopically. By the way, the same is true for claims of manufacturing to 'zero tolerance.'

"Our engineers tell us that this is technically unrealistic."

Smith: "How does the actual process work at ARP?"

"For each new design, we produce a number of prototype parts using different design aspects and sometimes different methods.

We inspect and test after each process, choose the best design and method of manufacture, and then freeze the design and write the manufacturing specification."

Smith: "You have mentioned the importance of fatigue resistance. Is there a difference in the procedures for strength and fatigue testing between aerospace and the specialty racing industry?"

"Yes. While the ultimate tensile strength testing is the same, fatigue testing is different. Aerospace fasteners are fatigue tested to the relevant specification of fluctuating tension load and number of cycles typically 130,000 cycles with the high tension load at 50% of the UTS and the low load at 10% of the high load. If all of the test samples last 85,000 cycles (per AMS 5842-D), the lot is accepted.

Fatigue, tensile and hardness testing are key quality control checks.

Even though racing fasteners are not continuously subjected to their maximum design load, at 18,000 rpm, 100,000 cycles takes just 5 minutes, thirty-four seconds. Except for drag racing, measured in seconds, no race lasts just 5 minutes. Therefore we consider this Aerospace Standard to be inadequate. At ARP, we fatigue test to elevated loads (10% above aerospace requirements) and to a minimum cycle life that exceeds 350,000 cycles. The majority of samples are routinely tested to one million cycles. During material development...and in the case of extremely critical new designs, we test to destruction.

Thread rolling is the last mechanical operation in our manufacturing process. For each production run the thread rolling machine is shut down after a few parts. These parts are inspected for dimensional accuracy and thread quality, and are physically tested for both strength and fatigue before the run is continued. Random samples are inspected and tested throughout the run. Extremely critical components are individually inspected for dimensional integrity."

Smith: "What about out-sourcing?"

"Economics often dictate that many processes in the manufacture of aerospace fasteners are farmed out. In the early days, ARP began as an out-source thread rolling shop.

Over the years, however, we have found, through experience, that the only way to maintain the quality we require is to keep everything in-house. From heading through machining, grinding, heat-treat, thread rolling, and shot-peening to black oxide treatment we perform every operation in house on our own equipment with our own employees."

Smith: "Gary, One of the things that I am hearing is that every aspect of the manufacture of racing engine fasteners is more expensive than that of similar aerospace items."

"True, but the bottom line is that we have to look at the cost aspect of the very best fastener versus the cost aspect of a blown engine and a lost race. In the end, the manufacturing of fasteners for racing comes down to a matter of attitude; a refusal to accept published standards and procedures as the best that can be done and most of all a determination to learn and to make still better products."

This interview originally appeared in the ARP catalog and has been a cornerstone of ARP's commitment to manufacturing excellence since 1968.